| Description: |

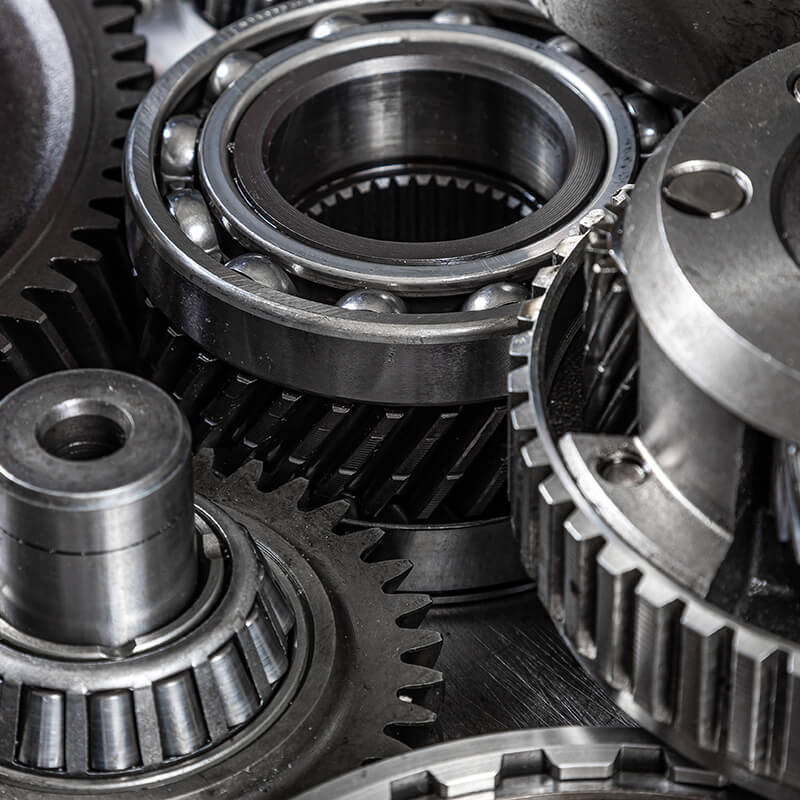

Kinetik Cutting Fluid is a water-soluble metalworking fluid of the traditional type. It is manufactured from high quality paraffinic base oils with added preservatives along with lubricity and anti-corrosion additives. The product is readily miscible with most mains water to form a stable, rich, milky white emulsion of low odour and good corrosion protection. Kinetik Cutting Fluid is non-staining to both ferrous and non-ferrous alloys and may be used in a wide variety of applications e.g., Turning (including light automatic work), milling, drilling, boring and shaping. |

| Properties: |

|

| Application: |

General Machining, free machining metals, non-critical grinding, ferrous and nonferrous alloys. |

Kinetik Cutting Fluid

Kinetik Cutting Fluid

Kinetik Cutting Fluid is a water-soluble metalworking fluid of the traditional type. It is manufactured from high quality paraffinic base oils with added preservatives along with lubricity and anti-corrosion additives.

The product is readily miscible with most mains water to form a stable, rich, milky white emulsion of low odour and good corrosion protection. Kinetik Cutting Fluid is non-staining to both ferrous and non-ferrous alloys and may be used in a wide variety of applications e.g., Turning (including light automatic work), milling, drilling, boring and shaping.

Kinetik Soluble Cutting Fluid

Kinetik Soluble Cutting Fluid has been formulated to meet the requirements for the preparation of water-soluble oils which will give stable milky emulsions in all types of water. It is using an additive which is a blend of emulsifying agents, wetting agents, and rust inhibitors, together with solvent refined mineral oils. It also contains biocides and fungicide additives to give the finished soluble oils and long service life, prevent emulsion breakdown and spoilage.

Available size: 200L / 18L

| Description: | Kinetik Soluble Cutting Fluid has been formulated to meet the requirements for the preparation of water-soluble oils which will give stable milky emulsions in all types of water. It is using an additive which is a blend of emulsifying agents, wetting agents, and rust inhibitors, together with solvent refined mineral oils. It also contains biocides and fungicide additives to give the finished soluble oils and long service life, prevent emulsion breakdown and spoilage. | ||||||||||||||||||||||||||||||||

| Application: | It is an extremely versatile product for medium-cutting operations, provides all the lubrication and cooling properties necessary to ensure good work piece finish, and extended tool life. It is suitable on ferrous and non-ferrous metals in turning, milling, drilling, tapping, threading and cold sawing operations. | ||||||||||||||||||||||||||||||||

The values shown above are typical values at the date of publication. KL Lubricants reserves the right to change these typical values without prior notice |

|||||||||||||||||||||||||||||||||

ENG

ENG 中文

中文